INSPECTIONS are often slowed by human factors, setting up safety barriers, ladders, harnessing/gearing up, climbing, assessing, and responding.

The use of UAS has reduced the need for some of these efforts, enabling inspectors to get eyes-on an inspection area very quickly without any additional effort beyond setting up the flight parameters and operational standards such as landing pads, cones, etc.

Inspections become significantly more safe, reduce time-on-target, and are a great component in identifying decision-quality-data (DQD).

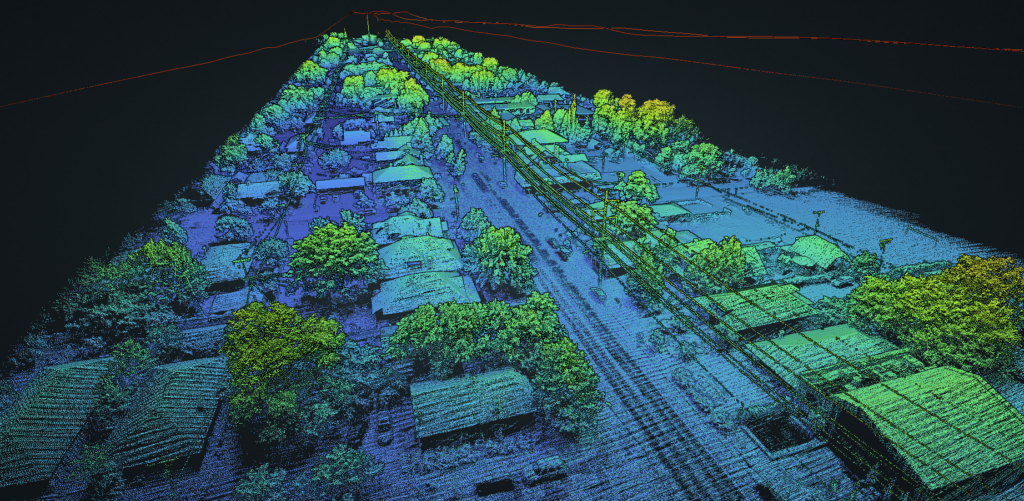

Photogrammetry and camera-determined UAS are ideal for inspections, while LiDAR also offers benefits, particularly when performing encroachment inspections, powerline sag, or scan-to-BIM inspections.

Flight under bridges, particularly metal structures, can be challenging if the right platform and pilot are not used. Some UAS manufacturers advertise their aircraft as “designed for bridges” yet have some very specific requirements about when and where their aircraft are capable of confident flight. Metal, concrete, passing vehicles all impact GPS signals and often cause multi-pathing. TLP pilots are trained, and use specialized equipment for this category of inspection.