Mining operations benefit from UAS/drones in many areas.

- Stockpile management

- Monitoring/Inspection

- Cut/Fill calculations

- Route Planning/Site Logistics

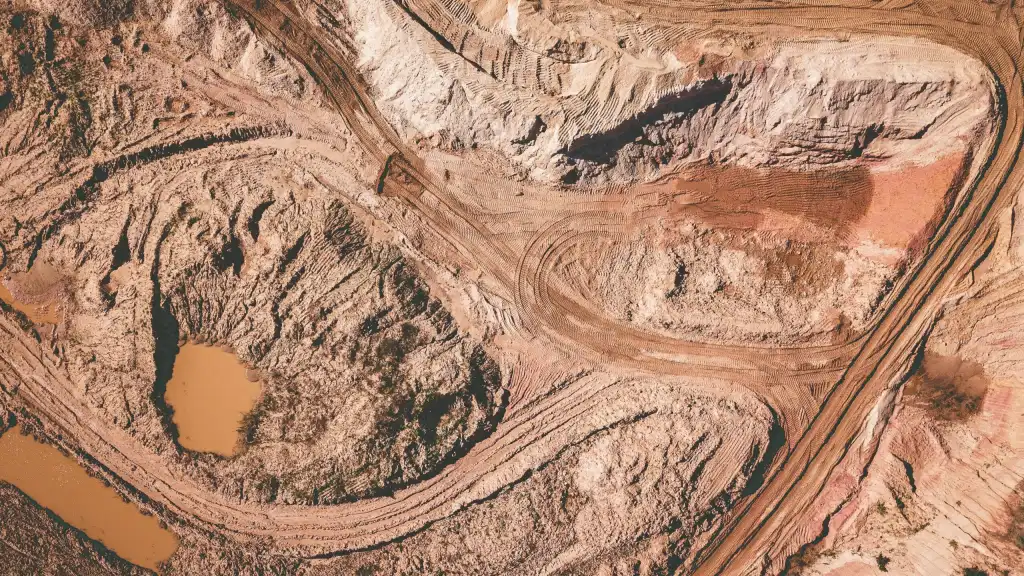

are just a few of the many areas where UAS are being implemented in Mining and Aggregate operations. Safety often requires significant expense, which may sometimes be eliminated through the use of UAS. For example, in the image below, this deep open-pit mine is extremely unstable, filled with toxic materials, and the client needed a close estimate of materials quantity to determine cost to fill the pit for site development.

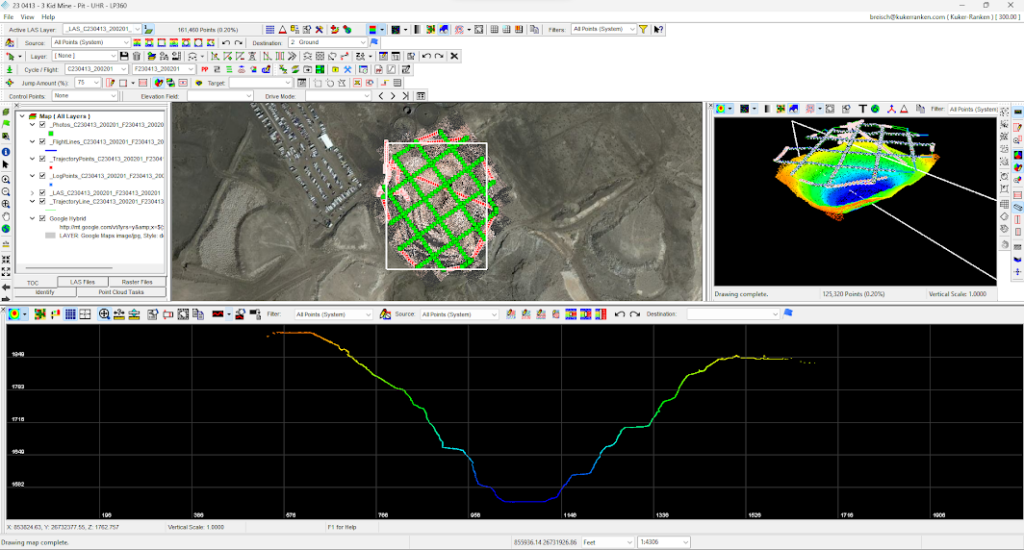

LiDAR provides near-instant feedback on high wall measurement, and data may be processed field-side for rough estimatations. Pilots and engineers or surveyors working together mine-side can efficiently and effectively focus on areas of interest, designing missions to provide high-confidence information.

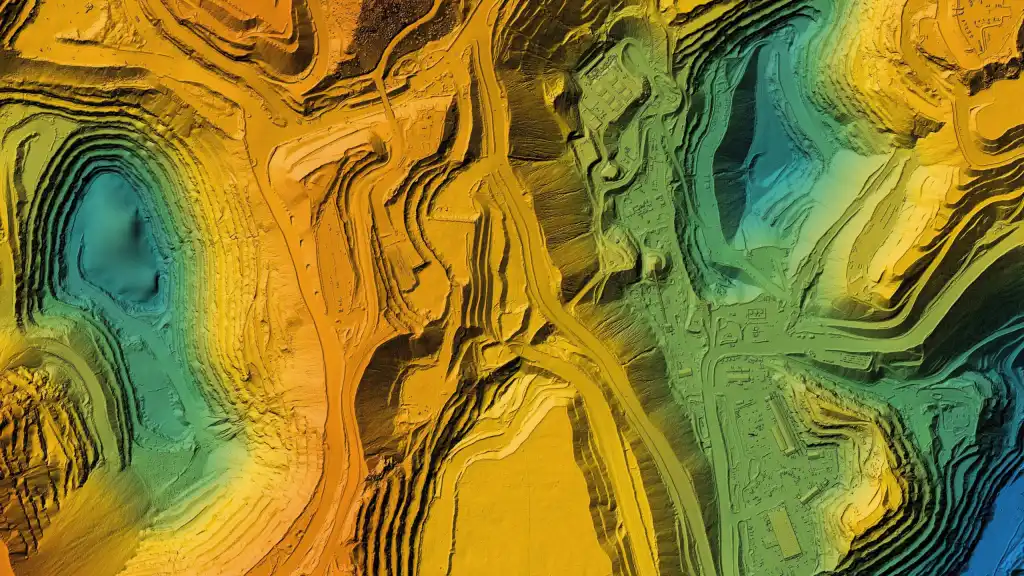

Mines benefit from Photogrammetry as well as LiDAR. Within the Utah, Idaho, Nevada region, TLP is often able to provide pilots and flights next-day, carrying either LiDAR or Photogrammetry (or both) payloads. Data turnaround often occurs same or next day, scale-dependent.